By CFOFC Ricky Ma

Kevlar-Reinforced Fiber Option for Drone Fiber Optic Canisters

In tethered drone communication systems, the optical fiber cable is not fixed. It unwinds from a canister as the drone moves. During this process, the fiber is exposed to tension, bending and possible abrasion.

Standard fiber optic cable performs well under typical optical conditions. But in applications where the fiber is constantly deployed and retracted, mechanical strength becomes as important as optical performance.

To address this, we offer a Kevlar-reinforced fiber option for our drone fiber optic canisters.

What Is Kevlar and Why It Matters

Kevlar® is a high-strength aramid fiber originally developed for protective and structural applications. It is widely used as a reinforcement material in fiber optic cable and other performance-critical products.

In fiber optic cable design, Kevlar (an aramid fiber) is placed as a strength member. Its purpose is to improve tensile resistance and mechanical durability. This structural layer does not carry optical signals, but it helps protect the glass fiber core from mechanical stress.

Kevlar in Optical Fiber: What It Does

Kevlar’s advantages include:

- High tensile strength relative to weight

- Good resistance to bending and abrasion

- Stable performance under heavy load

- Wide applications in industries such as aerospace, cables, and composite materials

In optical cable construction, Kevlar is typically used to:

- Absorb tensile stress

- Reduce stress on the optical fiber core

- Improve reliability under harsh conditions

Kevlar Reinforcement in Drone Optic Fiber Canisters

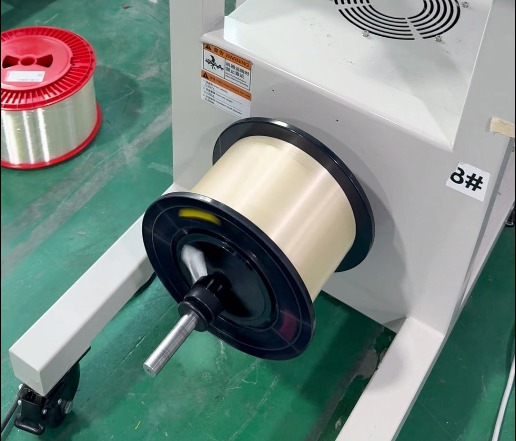

For drone fiber optic canisters, we offer Kevlar-reinforced fiber optic cable as a custom option. This can be used as an alternative to standard bare fiber when your project requires higher strength fiber optics.

This option is often selected for:

- Long-distance operation in harsh environments

- Complex flight paths with frequent changes in direction

- High-speed fiber optic deployment

- Potential for fiber optic cable breakage

The canister remains structurally the same, only the fiber type inside is changed.

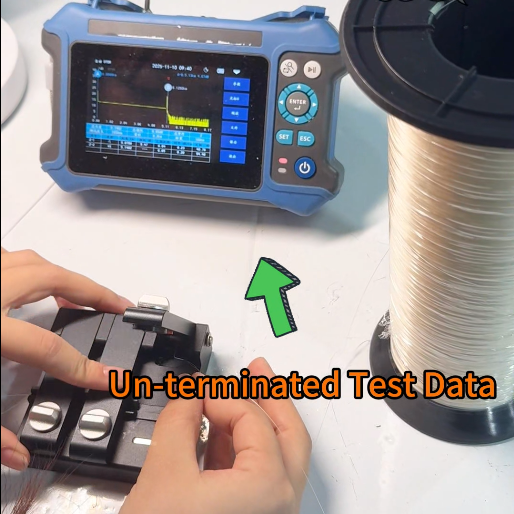

Manufacturing and Quality Control

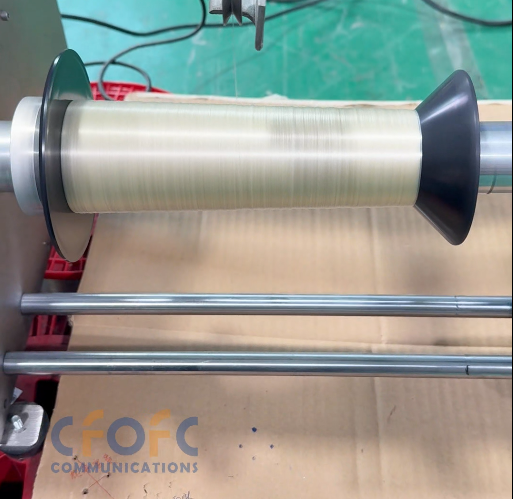

As a factory-based manufacturer, we handle the integration of Kevlar fiber and canister assembly in our own facility. Our production process includes:

- Material selection for fiber and aramid reinforcement

- Winding and assembly

- Inspection to ensure consistent behavior during unwinding

Every canister configuration undergoes quality checks before delivery.

Choosing the Right Solution for Your Project

Not all drone communication projects require Kevlar-reinforced fiber optic cables. For many easily manageable deployment scenarios, standard fiber optic cables are sufficient.

However, in situations requiring higher durability and tensile strength, Kevlar fiber optic cables offer a distinct advantage. Projects with longer deployment cycles, those subjected to significant tensile stress, or those requiring dynamic movement are well-suited for this solution.

About CFOFC

CFOFC provides fiber optic products and customized solutions for various communication systems. We focus on practical engineering design and stable manufacturing quality. If you have specific application requirements, we will provide you with professional technical consulting and comprehensive project support.